In order to maintain and improve quality and deliver products on schedule, we manufacture by effectively utilizing the systematically operated facilities and the know-how accumulated over the past 50 years since our founding.

Also, we plan and manufacture bags with regularity, stability, and complete originality here in Toyooka, the place of bag production. At the base of it all, there is the knowledge and integrated production techniques accumulated since our founding 50 years ago, and our production facilities that are ahead of other companies.

Evens out the thickness of leather.

Can be used for both hard and soft leather.

Evens out the thickness of leather.

Can be used for both hard and soft leather.

Both sides can be painted at the same time and dried automatically.

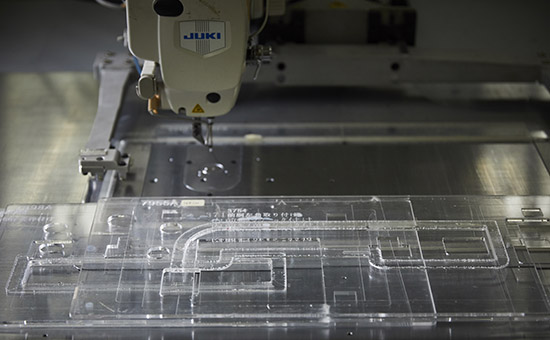

It is essential to choose an appropriate tool for each product to sew faster and more accurately.

It is essential to choose an appropriate tool for each product to sew faster and more accurately.

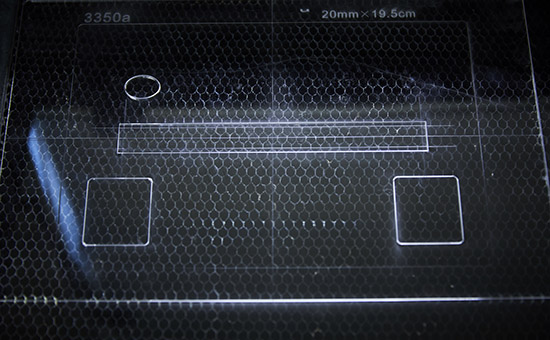

Used when sewing with a computerized sewing machine to increase its efficiency. The jigs are designed and manufactured in-house.

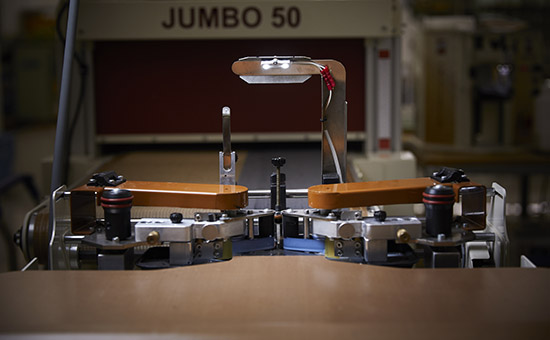

A three-dimensional effect is created with sewing alone, so that once it is finished, it looks as if it has a frame within it.

A three-dimensional effect is created with sewing alone, so that once it is finished, it looks as if it has a frame within it.

。

The aluminum frames are carefully inserted one by one to complete.

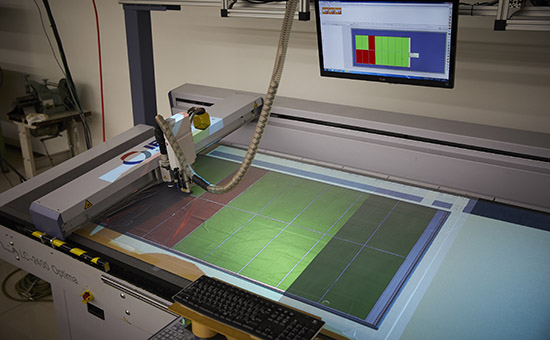

A machine capable of cutting leather and fabric is used to project data onto the material and block the leather.。

Since there are many small leather parts, clickers are also used.

Since there are many small leather parts, clickers are also used.

Partial skiving is performed according to the part.

Small pieces and items are painted by hand.

Small pieces and items are painted by hand.

In order to make the most of the heavy texture of the leather, we use a diamond needle with a No. 5 thread. The pitch is 4mm per needle, which is a little larger than the stitches used on a typical bag.

Special thread, which can only be used with hand sewing, is used for the handles and where the shoulder straps are stitched to the bag’s body. We put value on our stitching work to increase the strength and bring out the beauty of the design.

Special thread, which can only be used with hand sewing, is used for the handles and where the shoulder straps are stitched to the bag’s body. We put value on our stitching work to increase the strength and bring out the beauty of the design.

Enables efficient production by cutting each fabric to the appropriate size.

In order to make thick fabric look neat, we devise ways to reduce the thickness of where the fabric and leather overlap during the design phase.

The tongue on the front of the bag is sewn with a technique that does not overlap the threads which expresses a neat, minimal look.

In order to make thick fabric look neat, we devise ways to reduce the thickness of where the fabric and leather overlap during the design phase.

The tongue on the front of the bag is sewn with a technique that does not overlap the threads which expresses a neat, minimal look.

The metal accessories (rivets) and so on are carefully attached one by one.

The frames are carefully adjusted by hand to prevent their misalignment when closed.

The frames are carefully adjusted by hand to prevent their misalignment when closed.

A machine suitable for cutting fabrics. Capable of cutting fabric in layers and cutting according to data.

A machine that is capable of cutting both fabric and leather. The machine projects an image from above and applies the blocking. Fabrics can be cut in layers.

A machine that automatically paints both sides of the edge and then dries them with a heater.

Mainly used to produce jigs for computerized sewing machines.

This factory is the heart of Yuri’s manufacturing. In order to guarantee the value of “Made by Yuri”, it has advanced technology supported by cutting edge facilities and experienced sewers.

YURI CO.,LTD.

Head Office: 164-5 Kamikage, Toyooka City, Hyogo 668-0011 JAPAN

TEL: +81-796-23-5201 / FAX: +81-796-24-3607

Cutting machines : 22 machines

Sewing machines : 94 machines

This factory shares the know-how of the Toyooka Factory and has advanced technology that obtains millimeter units of precision. They mainly manufacture small items such as wallets and key cases.

Omiya Factory

Location:1996 Omiyachokuchiono, Kyotango, Kyoto629-2501 Japan

Cutting machines : 2 machines

Sewing machines : 98 machines

This factory can produce 300,000 units per month, and is always connected online with Japan, which allows for detailed communication. In order to share the know-how of the Toyooka Factory, there are regular opportunities for the technologists to learn in Japan.

。

YURI ABC DANANG Co., LTD

Location: Road No.10, Hoa Khanh Industrial Park, Lien Chieu District, Danang City, Vietnam

Cutting machines : 41 machines

Sewing machines : 403 machines

Monthly production volume: 300,000 units