Based on the process analyses we have accumulated over the past 50 years, we create jigs and manage production that is suitable to the product specifications, so that they can be smoothly mass produced.

There are two main reasons for mass production prototyping: first, to identify problems that may occur in mass production and to ensure the same quality as planned; second, to determine the machines, jigs, and process to be used in mass production and to prepare for efficient production.

At first, we identify all the processes and determine the order of work and the time required for each process. The notes for each process are also included in this analysis table. This table is essential for accurate scheduling and precise instructions during mass production.

At first, we identify all the processes and determine the order of work and the time required for each process. The notes for each process are also included in this analysis table. This table is essential for accurate scheduling and precise instructions during mass production.

By operating a process analysis table, we prevent errors of production quantity which could occur due to omissions during the process and work order errors. We can also find out if there are any bottlenecks throughout the processes and assign an appropriate number of workers for each part of the process. It is important for us in order to meet the delivery date.

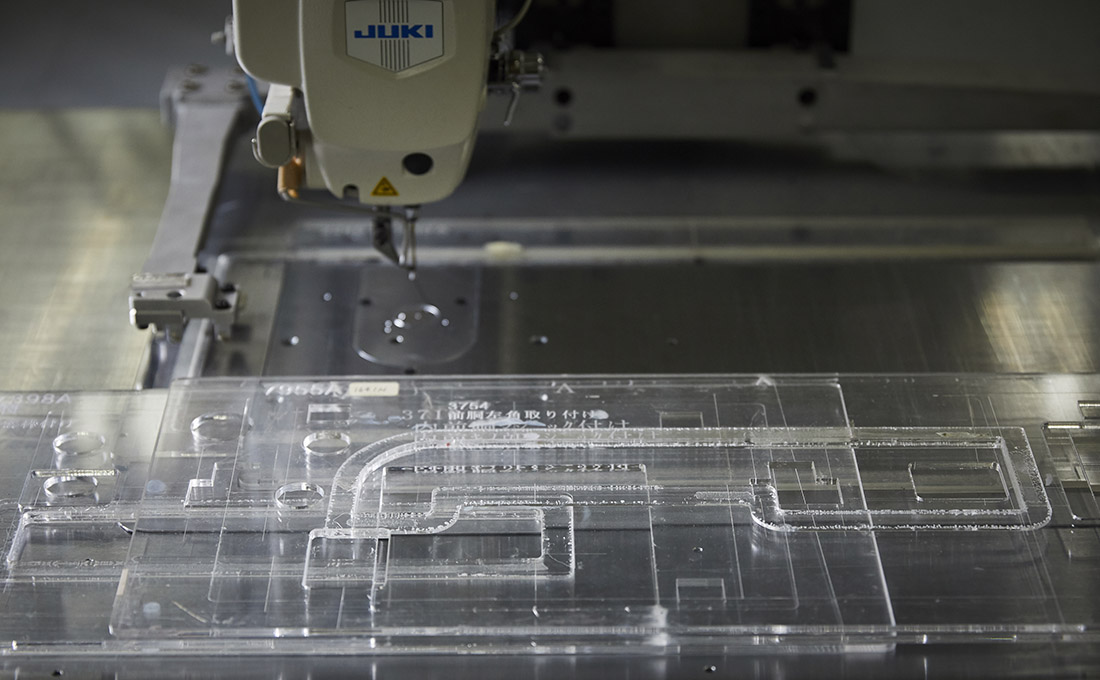

In order to improve the punctuality of our delivery rates, it is essential to manage the progress of each division such as material procurement, fabric/leather processing, the sewing line and computerized sewing machine line, and to communicate with each other. For this purpose, progress is reported at the twice-weekly production meetings and also at the twice-monthly adjustment meetings with the sales department, to check if there are any delays in each division. If there are any delays, we examine whether there are any divisions that can support the other division, and reallocate workers to improve the on-time delivery rate.

In order to improve the punctuality of our delivery rates, it is essential to manage the progress of each division such as material procurement, fabric/leather processing, the sewing line and computerized sewing machine line, and to communicate with each other. For this purpose, progress is reported at the twice-weekly production meetings and also at the twice-monthly adjustment meetings with the sales department, to check if there are any delays in each division. If there are any delays, we examine whether there are any divisions that can support the other division, and reallocate workers to improve the on-time delivery rate.